Dassault Systèmes JV with KUKA to enhance automation solutions in manufacturing sector

The collaboration addresses the growing global demand for industrial robots, a market currently valued at USD 16.5 billion. This market is projected to grow, with installations expected to reach 718,000 annually by 2026, up from over four million robots operating worldwide in 2024. Factors such as AI and energy efficiency are driving this growth.

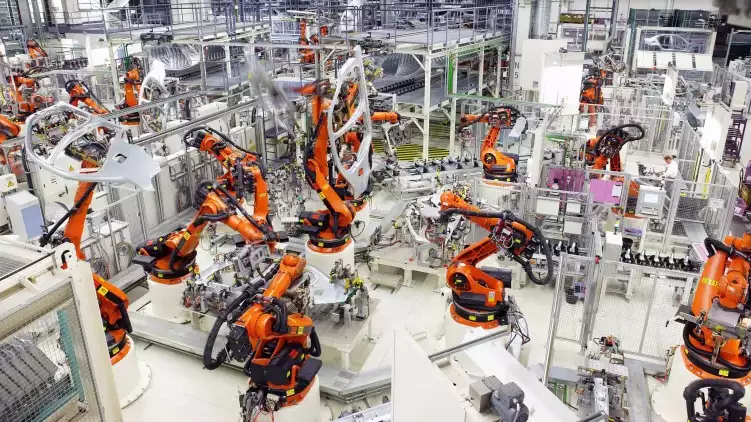

A step to automate factory operations

KUKA launched its mosaixx platform in 2024 to create an open and collaborative space for industrial software solutions. This cloud-based platform provides system integrators and engineers with access to various tools to digitalize and automate factory operations, regardless of machine type or manufacturer.

Dassault Systèmes' 3DEXPERIENCE platform offers virtual design, simulation, and engineering capabilities for products, processes, and infrastructure across various industries. This allows for real-time data analysis before physical production or implementation.

“Our collaboration with Dassault Systèmes enables us to expand our mosaixx portfolio with industry-leading virtual twin technology. Engineers can carry out simulations and analyses with real-time data while streamlined collaboration empowers system integrators with flexible applications for enhanced adaptability and innovation,” said Quirin Goerz, CEO, KUKA Digital.

Applicable across sectors

This partnership provides KUKA customers with a simplified method for acquiring and utilising Dassault Systèmes’ 3DEXPERIENCE platform and applications. It leverages virtual twin technology and collaborative features to develop more efficient and flexible solutions. The goal is to transform manufacturing operations for companies.

This partnership is intended to benefit companies operating in various sectors, including automotive, aerospace, electronics, metalworking, logistics, and healthcare. By integrating the 3DEXPERIENCE platform into the mosaixx ecosystem, both companies aim to contribute to advancements in robotics and automation solutions for manufacturing industries. The partnership seeks to streamline access and enhance the capabilities of existing systems.

“By partnering with KUKA, we can offer streamlined access to the 3DEXPERIENCE platform and our many applications such as CATIA, DELMIA and SOLIDWORKS. This will open up new possibilities for customers to benefit from the virtual world and collaborate and innovate in diverse sectors such as automotive, aerospace, electronics, metalworking, logistics, healthcare and more,” said Gian Paolo Bassi, Senior Vice President, Customer Role Experience, Dassault Systèmes.

The announcement of this partnership took place at the 3DEXPERIENCE World event in Houston. This event is specifically dedicated to the user community of SOLIDWORKS and the 3DEXPERIENCE platform. The partnership aims to address the increasing demand for advanced robotics and automation solutions within various manufacturing sectors.