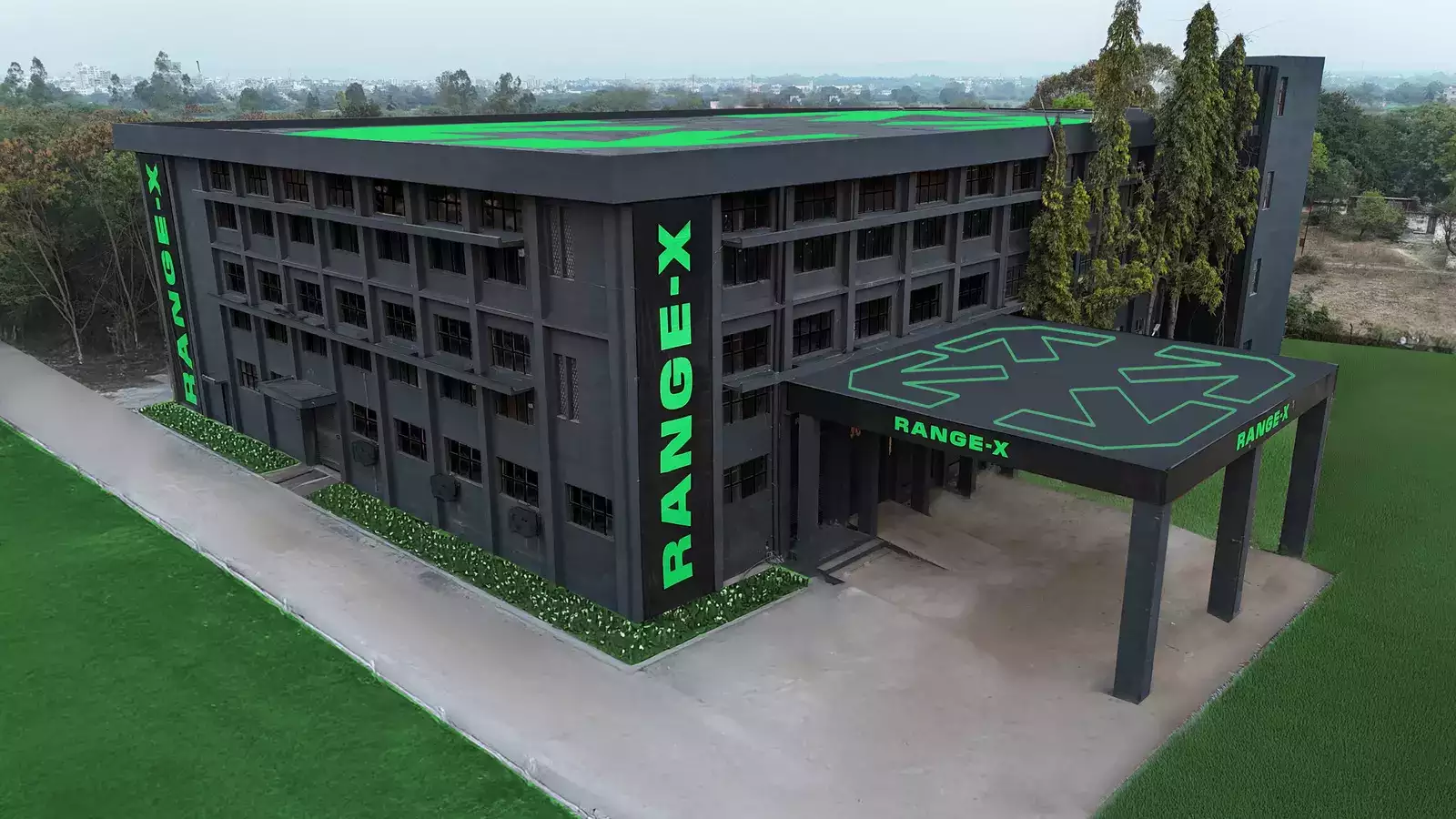

Kinetic Group opens battery manufacturing facility in Ahmednagar

The company aims to supply these batteries to other original equipment manufacturers (OEMs) as well. This move marks Kinetic Group's entry into the EV battery manufacturing sector. The company expects to benefit from the projected growth of the Indian EV market, estimated to reach $18.319 billion by 2029.

The Ahmednagar facility will produce both Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC) batteries. The facility will cater to the growing demand for two-wheeler EV batteries and is developing prismatic cells for three-wheelers.

Kinetic Group's Range-X batteries utilise LFP technology, known for its thermal stability and performance in extreme temperatures. These batteries incorporate smart Battery Management System (BMS) integration for enhanced efficiency and battery health. The batteries are designed with eco-consciousness, using non-toxic, recyclable, and ethically sourced materials.

The NMC batteries will focus on high energy density for longer-lasting power. They are designed for superior performance with a high charge-discharge rate, suitable for demanding conditions, the company said in a media release.

Commitment to innovation and sustainability

Ajinkya Firodia, Vice-Chairman and Managing Director, Kinetic Group, said, “Range-X is a result of pioneering work in batteries and a significant step towards India’s mobility transformation. The Ahmednagar facility represents our dedication to self-reliance, safety and sustainability in battery technology.”

The Ahmednagar facility features an automated production line equipped with IoT-enabled POKE-YOKE systems and stage-wise inspections. These systems ensure precision, quality, and adherence to industry standards such as AIS 156 and AIS 004.

Kinetic Group is also focusing on advanced technology and localisation of the BMS. They are aligning with the Production Linked Incentive (PLI) schemes under the government's 'Make in India' initiative.